Our group finished the major work of our hardware of Deemo, which is our music game project’s name for the playful city. There were two parts, product component and circuit, focused on to deliver our final design. Most of the work was processed in the DMAF Lab with the advice and help of the staffs, such as the selection of material, the technical advice about material processing. All of our team members were involved in this task and most of the work was done by me.

For the components, the materials we used was found in the recycle section in the lab because the size of our project is relatively small compared with others. The materials in the laboratory are enough to meet our needs. We picked a white particleboard and white foam as our main material.

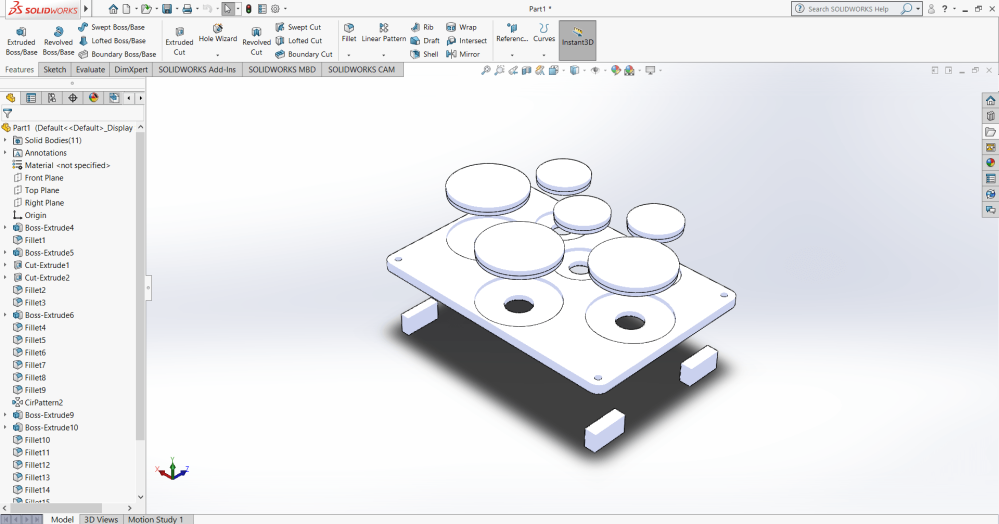

As shown in 3D model which was created by Solidworks, there should be 6 buttons made by white foam, 1 board made by particleboard, and 4 supporters made by wood.

We drilled six group holes on the board to place the buttons. The holes have two layers, a small one go through the board and a larger one not, each group has a common centre. we drew circles on board to ensure the size and position of holes.

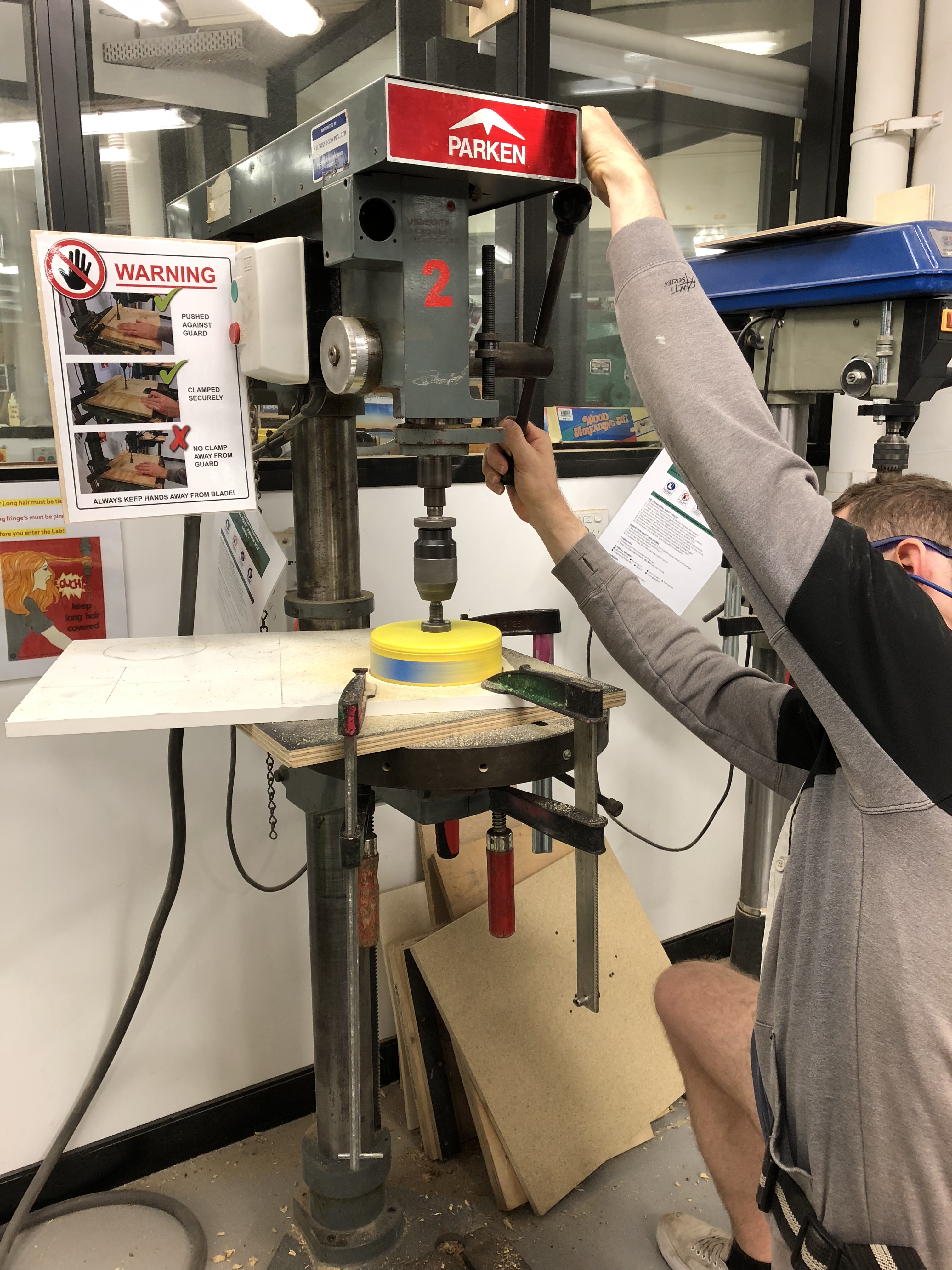

Then, we asked the assistance of the staff who taught us how to use the equipment in the lab to drill. Firstly, we drill the centre of the circle through to fix positions.

Secondly, 2 types of bowl shape drillers, different diameters which was slightly larger than what we designed previously, were used to limit the size of circles because the upside buttons are larger than the downside buttons. The nice staff helped a lot in selecting the appropriate types of equipment and instructions. After installing the bow shape driller and fixing our board, we needed to match the driller to the correct position of the board. This driller should be controlled carefully to reach a certain deep which is about half of the thickness of the board. A blue tape was used as a mark to remind us how deep we were now.

After finishing this part, we needed to remove the extra material in these circles to make room for the buttons. A new hand router was introduced to us which is powerful to drill on a surface with the set depth as a highly dangerous equipment.

The result was amazing that achieved what we wanted. However, the new surface was not smooth enough. Some manual work was helpful to polish the component. We made the corner of the board becoming fillet and reduced the roughness of new surfaces.